Understanding Polyurea and Polyurethane Bedliners (In Laymen's Terms)

Some articles covering Polyurea and Polyurethane come off sounding like you need a Ph.D. in science to comprehend what is being discussed. Instead of going into boring detail of the complex chemical reactions such as step-growth polymerization, and the chain reactions that take place to provide you with that tough bedliner, this article will go over the basics and of the various physical properties of polyurethane and Polyurea, as well as poly hybrids in a way that most can understand. We will present the details here and discuss more in future blog posts. Anyone planning to employ the use of bedliner and other types of coatings, ought to take a look and see what you can learn.

Polyurea

Polyurea is a process which requires specific types of chemicals and efficiently uses similar chemicals to various materials in various environments. It is an independent product. It is impervious to abrasion and tear due to its superior tensile strength.

Polyurethane

There is always a compromise that needs to be made when it comes down to altering physical properties. Polyurethane is flexible and is much softer than polyureas. Polyurethane is a spray liner that polyurethane spray liner has a higher risk of being susceptible to being smashed more than Polyurea due to the smaller tensile strength. This is a discussion of materials that are extremely strong in resisting puncture tear and gouge. This does not mean that this material will be less resilient over that of polyurea model.

Poly Hybrids

Poly Hybrid is a combination of Polyurea and polyurethane that provide the most advantages with no compromise. To offer texture and anti-slip properties, many various paint and rubber chips are typically added.

Poly liners stick to the surface using mechanical methods and not chemically. They require small grooves or ridges to keep them in their place. This is the reason liners need the most thorough cleaning and sanding. Polyurea is able to be sprayed directly on frozen or liquid ice, but, polyurethane (and hybrids) aren’t. Therefore, do not spray the vehicle once it’s been outside under the rain. If you apply Polyurea the surface of the vehicle must be dry.

Application Method

Beware of the distinction between high and low-pressure temperatures.

Polyurea requires extreme pressure.

Although the terms may be confusing There are two kinds of pressure: high and low. The gun that is applied with the lower pressure will have more influence over its surface. This is crucial because liners typically don’t make use of aggregates and the gun creates the non-slip surface. Another false name is “hot” (or “cold,” because liner chemicals have an exothermic reaction once they exit the gun. This creates an increase in temperature. There are hot and cold applications. The chemicals can reach temperatures of 230–230F for cold and hot applications. They can reach 140–130F when they are heated.

Low-pressure cold applications produce the creation of a flexible and elongated product. The use of hot pressure results in the product becoming more rigid and stiff however, it is not as flexible.

Curing Time

It must be dry prior to you get it in your hands. It must be dry prior to being capable of carrying your weight on the most recent liner securely. The hot sprays dry in just 3–5 seconds, however cold ones may be dry in 20 to 25 minutes. Hot sprays are the ideal choice when you want for spray in a downward direction, like in ceilings. Spray-ins take approximately 24 hours for drying.

UV Stability

In essence, every product will eventually start to fade. Although some companies may include ultraviolet inhibitors into their product while others may apply them as coatings. coating. It’s just a matter of time. Accept it.

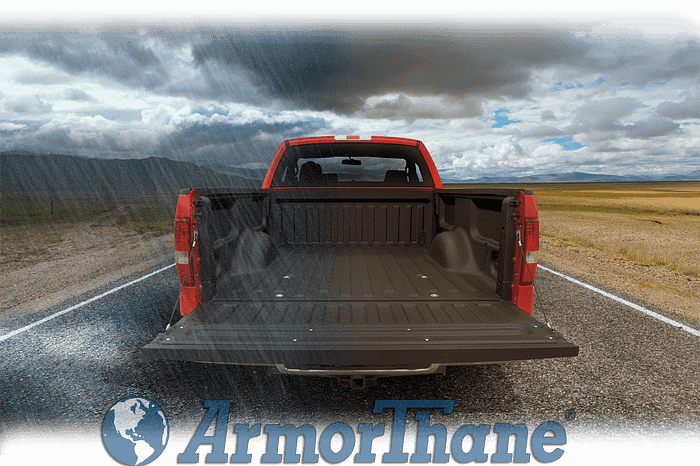

If you’re looking to be the highest quality with the most beautiful appearance and the best quality product and the most effective way to use it, you have only one option. The answer is ArmorThane. With over 30 years of experience they’ve been able to transform the way they conduct business and the way they do business. The company was among the very first firms to offer Polyurea in addition to polyurethanes for bedliner. Through the development of new products like ArmorLiner they have set the bar even further for other companies who want to compete. With exceptional chemical properties such as it’s tensile and tear-resistant resistance shore hardness, and elongation, ArmorLiner has proved to be efficient in virtually every use. It has now occupied the number one spot for most frequently purchased polyurea products in the US over the last few years.

Visit this page to learn more information about ArmorLiner, and the information you should learn about how you can become a bedliner applicator.